INTRODUCTION

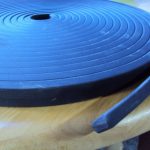

Rockmax Hydrostop CJ is hydrophilic rubber sealing material. The product can use for construction joints, precast concrete joints and tunnel segments. The product comprises of high grade rubber based material and special grade resin. Rockmax Hydrostop CJ will expand when contact with water to fill up gaps and voids. The material can expand and shrink to its original dimension in several times from wet and dry stage cycle.

AREA OF USES

ADVANTAGES

APPLICATION AND INSTALLATION

PREPARATION

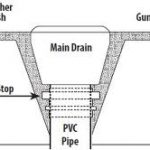

The surface of joints must be clean and free from dust, cement paste, mould oil, standing water and loose particles. A groove must be form by using rigid material such as metal strip form to achieve good profile. The groove dimension should be bigger than waterstop profile by approximate 1-2mm. The minimum concrete covering is 50mm.

APPLICATION

Apply Rockmax Adhesive 11 along the groove and wait until tacky prior to install waterstop. For rough surface joint, Epoxy adhesive should be use. Press Rockmax Hydrostop CJ into the groove. Make sure no standing water along the surface. Nail can be used to fix waterstop in position. Joining waterstop by butt joint only.

PACKAGING

20mm x 10mm x 10Meter.

Different size is available upon request.

STORAGE

Storage in cool and dry condition free from frost, water, moisture and high temperature. Avoid sunlight. Store in temperate between +5°C to +45 °C degree.