INTRODUCTION

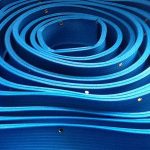

Rockmax Adhesive 11 is a one part, ready to use contact adhesive based on polychloroprene. It can be used for installation hydrophilic rubber waterstops on dry concrete substrates.

AREA OF USES

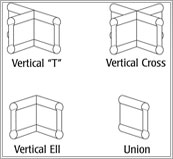

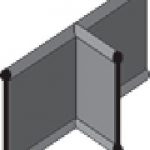

Rockmax Adhesive 11 can be used as adhesive for hydrophilic rubber waterstops on dry concrete substrates.

ADVANTAGES

APPLICATION AND INSTALLATION

PREPARATION

The concrete substrate must be sound, clean, dry and free from oil, mould oil, grease, dust, dirt, cement paste and loose contaminants. In case of dust and dirt we recommended clean by compressed air. Do not use water to clean.

APPLICATION

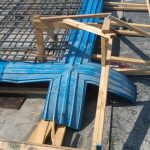

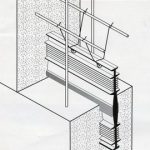

Apply Rockmax Adhesive 11 by brush on both adhere surface. All area of surface to bond must be cover with adhesive. Wait the adhesive to initial cure (or touch dry) at approximate 5-10 minutes depend on ambient temperature but no longer than 30 minutes. Press the rubber waterstop on the surface with constant pressure along the length of the joint. Use rubber hammer or steel roller for making rubber waterstop perfectly attached to the concrete surface. Allow the adhesive to cure at approximate 30 minute. Fully cure in 24 hours.

PACKAGING

650 gram

15kg

STORAGE

Storage in cool and dry condition free from frost, water, moisture and high temperature. Avoid sunlight. Keep container tightly from air or moisture. Storage at temperate below 30°C degree.