+66 2 864 8658

Author: admin

ROCKMAX APEX MIXER 1600

1600 WATT HEAVY DUTY ELECTRIC

INTRODUCTION

Rockmax Apex Mixer 1600 is a heavy duty electric mixer. The tool set include with steel paddle for ready to use on site.

AREA OF USES

Rockmax Apex Mixer 1600 can use to mix with varieties of materials such as concrete, cement mortar, tile adhesive, tile grout, paint, waterproofing materials, epoxy, polyurethanes and all construction chemical products.

ADVANTAGES

APPLICATION AND INSTALLATION

HOW TO USE

Please read the manual attached in the box before start using.

PRECAUTION

Keep out of reach of children. Follow safety standard for electrical tools and equipments.

ROCKMAX PU FOAM M76

1-PART MULTIPURPOSE POLYURETHANE FOAM

INTRODUCTION

Rockmax PU FOAM M76 can be used include with fixing and insulation door and window frames, filling and sealing gaps, joints, cavities, pipe penetrations, wireways, electrical outlets, aircondition pipes. Also to use with any filling that need to close the area for sound or weather proof purpose.

AREA OF USES

Rockmax PU Foam M76 can be used include with fixing and insulation door and window frames, filling and sealing gaps, joints, cavities, pipe penetrations, wireways, electrical outlets, air-condition pipes. Also to use with any filling that need to close the area for sound or weather proof purpose.

ADVANTAGES

- High expansion rate and foam stability.

- Excellent adhesion and bonding to many substrates such as PVC, teflon, silicone, concrete, wood, steel, etc.

- Thermal and acoustical insulation.

- Easy application.

- Foam can be cut, trim and shape.

- Age resistance.

- Fast setting and curing.

- Not contain CFC, HCFC.

APPLICATION AND INSTALLATION

APPLICATION

Shake the can well before use (20 times). Screw the adapter on the valve. Hold the can upside down and activated the foam by pressing the valve. Moisturizing the surfaces and the foam improves adhesion and shorten curing time. Fill foam by layer to layer. Wait for each layer to cure until material is hard enough.

PACKAGING

500 litre.

STORAGE

Storage in shade and dry condition at +15 to +30ºC. Avoid from sunlight, frost, water, moisture and high temperature. The freezing point is approximate -3ºC. Max shortage temperature is +50°C degree. Store in transported vertical position.

ROCKMAX AQUATECH S

Silane-Siloxane Solvent Base Water Repellent

ข้อมูลเบื้องต้น

Rockmax Aquatech S คือนํ้ายาเคลือบผิวสําเร็จรูป พร้อมใช้งาน สูตรมีตัวทําละลาย ผลิตภัณท์ทํามาจาก โพลีเมอร์ ไซเลน ไซล๊อกเซน โดยจะแทรกซึมผ่านเข้า ไปในเนื้อของพื้นผิวและคงอยูทนทาน ใช้สําหร ับปกป้อง ผิวจากคราบน้ำ ตะไคร่นํ้า ทําให้พื้นผิวสวยงาม ทนทาน สามารถซึมผ่านพื้นผิวที่มีความแน่นได้ เช่น คอนกรีตผิว มัน จะช่วยให้สามารถปกป้องคอนกรีตเสริมเหล็กจากการ กัดกร่อนได้ดี

ลักษณะการใช้งาน

Rockmax Aquatech S ใช้สําหรับ เคลือบ ปกป้องผิว คอนกรีตโครง สร้าง เช่น สะพาน ทางด่วน ทางยกระดับ สนามกีฬาปูนเปลือย

คุณสมบัติ

วิธีการติดตั้งและใช้งาน

การเตรียมพื้นผิว

พื้นผิวคอนกรีตต้องสะอาด ไม่มีฝุ่น ผงซีเมนต์ นํ้ามัน นํ้ายาทาแบบหลงเหลืออยู่ คอนกรีตหรือปูนฉาบใหม่ต ้อง รออย่างน้อย 21 ว ันก่อนทำการทา ปูนซ่อมแซมผิวใหม่ ต้องรออย่างน้อย 5 วันก่อนทำการทา

วิธีการใช้งาน

ทาน้ำยาด้วยแปรงหรือลูกกลิ้ง รอให้แห้ง 24 ชั่วโมงก็สามารถ ใช้งานได้ ในกรณีที่พื้นผิวมีความพรุนมากให้ทาซ้ำอีกครั้ง โดยรอ 2 ชั่วโมงหลังจากทาเที่ยวแรก

การบ่ม

ป้องกันพื้นผิวที่ทาเสร็จแล้วจากน้ำและฝนหลังจากทา 24 ชั่วโมง โดยการบ่มตัวจะสิ้นสุดที่ 7 วัน

ขนาดบรรจุ

5 ลิตร ,

25 ลิตร

วิธีเก็บรักษา

เก็บรักษาไว้ในทีม ไม่มีแดด ความร้อนสูง หรือความชื้น ควรเก็บรักษาไว ้ที่ อุณหภูมิประมาณ 10 ถึง 40 องศาเซลเซียส

ROCKMAX AQUATECH W

Silane-Siloxane Water Based Water Repellent

INTRODUCTION

Rockmax Aquatech W is a ready to use, water based, liquid applied, water repellent. It’s formulated from silane-siloxane polymer. The cured material act like sealer to the substrates and provides durability, water repellent and protect the appearance of surfaces. The material penetrates into the surface, forming a long lasting water repellent treatment that retards the penetration of these contaminants.

AREA OF USES

Rockmax Aquatech W can be used to many substrates include exposed concrete, cement mortars, masonries, bricks, tiles, natural stones, lime stones, slate, terracotta, clay tiles. It can be used also for re-waterproofing for finished tiles.

ADVANTAGES

APPLICATION AND INSTALLATION

SURFACE PREPARATION

The substrate must be dry, sound, clean and free from oil, grease, mould oil, curing compound, dust, loose particles and cement paste. No standing water on the surfaces. New concrete should be allowed to cure at minimum 21 days old. The new repair mortar must be waited at minimum 5 days before application.

APPLICATION

Stir the material until homogenous by electric low speed drill mixer. Apply Rockmax Aquatech W by roller or brush. Apply with a uniform saturation. Surfaces should remain wet for a few minutes. Water and oil repellency will start to develop within 24 hours and completely cure in 7 days. In case of porous substrates, we recommended to apply the second coat within 4 hours after first application

PACKAGING

5 litre.

25 litre.

200 litre.

STORAGE

Storage in shade and dry condition at 5-40ºC. Avoid from sunlight, frost, water, moisture and high temperature.

ROCKMAX PUTTY

ACRYLIC WALL PUTTY

INTRODUCTION

Rockmax Putty is a waterborne, acrylic putty for interior and exterior use. It has excellent resistance to adverse weather conditions, damp, alkalinity and is suitable for coating of plaster, concrete, cement boards, plaster boards, gypsum boards. The material is smooth and fine surface, Easy to work and quick drying without cracks.

AREA OF USES

Rockmax Putty can be used to fill the holes, voids, joints, cracks, seams for concrete, gypsum boards, cement boards, plaster boards, woods, brick works, block works, mortars, tiles.

ADVANTAGES

APPLICATION AND INSTALLATION

SURFACE PREPARATION

The substrate must be sound, clean free from oil, grease, mould oil, dust, and loose particles and cement paste.

APPLICATION

Apply material by spatula or steel trowel.

PACKAGING

5 kg.

STORAGE

Storage in shade and dry condition at 10-40ºC. Avoid from sunlight, frost, water, moisture and high temperature.

ROCKMAX PLASTECH

Cement Mortar Admixure For Rendering

INTRODUCTION

Rockmax Plastech is a liquid type admixture for cement mortar mixing. It can be used for rendering, plastering and block/brick laying works. The mix provides high quality mortar results in excellent bo nding, reduce cracks, reduce amount of water, enhance workability, easy to work. The material is conform to BS 4887.

AREA OF USES

Rockmax Plastech can use by mix with water, cement and sand to provide high quality cement mortar for rendering, plastering, block works, brick works.

ADVANTAGES

APPLICATION AND INSTALLATION

DOSAGE

0.1 – 0.2% by weight of cement.

MIXING

Mix admixture follow above mix ratio with clean water before mix with sand and cement.

PACKAGING

5 litre,

25 litre,

200 litre.

STORAGE

Storage in shade and dry condition at 10-40ºC. Avoid from sunlight, frost, water, moisture and high temperature. The freezing point is approximate -3ºC.

ROCKMAX ADMIX CM

Waterproofing Admixure For Concrete & Mortar

INTRODUCTION

Rockmax Admix CM is a liquid admixture for waterproofing and plasticizer for concrete and cement mortar mix. Rockmax Admix CM conforms to ASTM C494 type A.

AREA OF USES

Rockmax Admix CM can be used to waterproofing concrete structures such as watertanks, swimming pools, toilets, kitchens, ground slabs, tunnels, culverts and can use for waterproofing cement mortar rendering.

ADVANTAGES

APPLICATION AND INSTALLATION

DOSAGE

0.4– 0.5% by weight of cement. Must be dispensed with clean water. We recommended that the trial concrete mix must be proceeding on site with actual materials. To determine the best optimum dosage, the result such as compressive strength, slump, setting time and etc should be analyzed carefully. For more information and assistance please contact Rockmax Technical Services Team.

PACKAGING

5 litre,

25 litre,

200 litre.

STORAGE

Storage in shade and dry condition at 10-40ºC. Avoid from sunlight, frost, water, moisture and high temperature. The freezing point is approximate -3ºC.

LOXET 600

ALKALI FREE LIQUID ACCLERATOR

INTRODUCTION

Loxet 600 is an alkali free liquid set accelerator admixture. It’s especially design for shotcrete application.

AREA OF USES

Loxet 600 can be used for sprayable concrete application including with tunneling, rock support, soil stabilization, mining support, pool constructions.

ADVANTAGES

APPLICATION AND INSTALLATION

DOSAGE

The consumption of Loxet 600 depends on many factors such as temperature, type of aggregates, cement content, age of cement, thickness per layer, method of spraying, equipment, accurate of nozzle, setting time, design strength, etc. We recommended the dosage of Loxet 600 in between 3% to 10%. The optimum dosage must be determined by trial on site with control conditions. Overdosing (>10%) may result in decrease of ultimate strength.

COMPATIBILITY

Loxet 600 is compatible with all type of ordinary portland cement. We recommended to used fresh cement than aged cement as there may have some effect on setting time. Loxet 600 is compatible with all Rockmax admixture products. Do not mix Loxet 600 with any type of accelerator produced by other manufacturer.

APPLICATION

Loxet 600 must be added in the nozzle and injected by pump with adjustable pressure type (No filter on nozzle head). We strongly advise that w/c ratio must be lower than 0.45 and should be use conjunction with our superplasticiser admixture for improve smooth pumping.

CLEANING

All equipment, pump, hose, nozzle, etc must be truly clean with plenty of water.

PACKAGING

200 Litre PE type drum.

Do not store material in steel containers. The container must be sealed to avoid evaporation

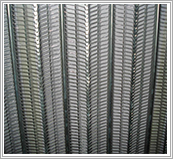

ROCKMAX RIBLATH

3/8” GALVANISED STEEL LATH

INTRODUCTION

Rockmax Riblath is the most rigid of all metal laths. With full 3/8” ribs longitudinally spaced at 4” apart. This lath can be used both vertical and horizontal applications. It is designed to provide durable, effective for plastering and rendering work at job site. It is manufactured from pre-galvanised steel or stainless steel as per request.

AREA OF USES

Rockmax Riblath is ideal for refurbishing damaged or aged masonry walls, when a key for rendering is not certain due to disintegration or softening of the wall face. It can be use as the permanent construction joint for concrete slab if necessary designed. It can be use for internal or external applications.

ADVANTAGES

APPLICATION AND INSTALLATION

Fixing of Rib lath Sheets

Rib lath is fixed so that the tip of the rib is put against the supporting background. The rib of the sheet should run at right angles to any supports. Make sure that sheets are superposed by a minimum of 50mm end to end and by 25mm width ways and that the ribs are nestled together.

Wood Support

Rib lath is fixed at each rib to wood supports using plasterers’ nails or staples. Make sure that compatible corrosion resistant fixings are used, for example, please don’t use galvanized fixings for stainless steel.

Metal or Steel Support

Rib lath is fixed at each rib to metal support using 1.63mm galvanized or stainless steel tying wire. When joining rib lath sheets overlap the edge ribs and tie the edges with 1.22mm tying wire at 150mm centers.

Solid Background

Rib lath can be fixed to a solid background using a suitable fixing which holds the ribs firmly against the background. Where sheets are installed perpendicularly, fixings should be positioned through all ribs at 600mm centers to make sure there have enough stability. Movement joints should be provided at maximum 50mm center (vertically and horizontally) for render finishes.

STORAGE

Storage in shade and dry condition, Avoid from frost, water, moisture and high temperature.