INTRODUCTION

Rockmax AC GEL is a low viscosity, environmentally friendly, acrylate injection system. It is able to spread to fine soil and fill voids between interface areas of the concrete and substrate. This injection system provides excellent waterproofing capabilities for use in the creation of grout curtains behind existing concrete walls or abutments. It can create solid, homogeneous membranes beneath concrete floors as well as stabilizing soil and filling voids at the building foundation and interface areas. Their hydrophilic properties provide a lasting and durable barrier against moisture and water pressure intrusion. It non-toxic chemical that can use with portable water tank and underground.

AREA OF USES

Rockmax AC GEL can be used to create water barrier, soil stabilization and curtain grouting underground including with tunnels, subways, sewages, water tanks, retaining walls, dams, canals, shafts, basements, construction joints, expansion joints, crack filling, leakage of concrete structures and brick or block gap filling. Protect moisture movement from underground.

ADVANTAGES

APPLICATION AND INSTALLATION

PREPARATION

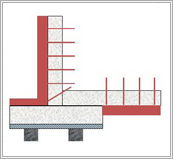

It is necessary to analyze the nature and state of the building and to examine the foundation soil before making new sealing surface (curtains) in building components in direct contact with the foundation soil or within the existing structure. Such an analysis provides the necessary information on the feasibility of the planned injection measures and the materials consumption rate to be expected. The results of this analysis are decisive for positioning the drill holes to be made for the building project. Standard paterns: gel injection into the foundation soil in the form of a vertical curtain and horizontal floor.

MIXING

APPLICATION – Curtain injection

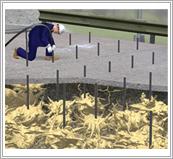

Install injection packers in the drill hole. Inject the AG gel from bottom to top (beginning at the lowest point). Proceed with the injection process until the emergence of material of the gel formation in the adjacent drill hole. The reference value for the gel’s consumption is approx. 5 to 60 kg/m2 depend on soil condition. Strongly cohesive, very dense soil will provide a low consumption rate while sandy soil or even large rocks behind the structure increase consumption rate.

FINAL WORK

The packer can be removed immediately after the gel formation. Mechanical packers cleaned by means of rinsing pump (water) can generally be used again. After dismounting the packers, remove all gel from the drill holes and fill with concrete repair mortar (Rockmax TOP) or quick setting cement mortar for brick work (Rockmax Waterplug).

PACKAGING

Part A: 20kg, accelerator: 150gram

Part B: 20kg

STORAGE

Storage in shade and dry condition free from frost, water, moisture and high temperature. Rockmax AC GEL must be store in air tight container. Must protect from atmospheric moisture. Must be store in area where temperature around 10ºC – 25ºC degree.