INTRODUCTION

Rockmax Hyband joint system is the system use for high movement and high resistance of chemical and water ingress to joint of buildings or structures. The system consists of hypalon rubber membrane and two part epoxy adhesive. Its design to subject to high movement such as joining between two buildings that conventional gun applied sealants can not be used.

AREA OF USES

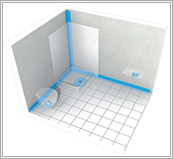

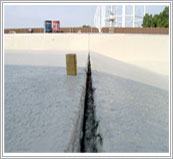

Rockmax Hyband can be used to seal joint in car park decks, podiums, balconies, walkways, basements, swimming pools, silos, tunnels, bridges, water tanks, immersed water structures and use to seal crack on concretes.

ADVANTAGES

APPLICATION AND INSTALLATION

PREPARATION

The joints must be clean and dry. Remove all dirt, dusts, cement pastes, oil, grease and other contaminants. Concrete substrate age must be minimum 4 weeks old. Make sure the joints are in good condition and good shape. The repair and structural sound of joint surface is required by mechanical mean. Joints edge must be straight and sharp. Damaged joints edge must be repair by epoxy mortar or consult Rockmax for further advice.

APPLICATION

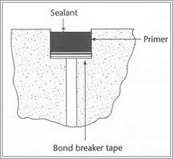

1. Apply the epoxy adhesive along the side line of joint with 2cm beyond the membrane. Apply adhesive thickness is approximate 1-2mm.

2. Lay the membrane on the epoxy adhesive within 30 minute. The membrane must lay at 5cm from edge of joint.

3. Press the membrane using pressure rollers until the adhesive protrudes through punch-holes of the membrane.

4. Finish by applying 1 or 2mm coat of epoxy adhesive on top of membrane.

5. Allow the epoxy adhesive to dry approximate 45 minute before subject to water.

PACKAGING

Roll length: 20meter

STORAGE

Storage in shade and dry condition. Avoid from frost, water, moisture and high temperature (min-max +5 to +40ºC). Do not expose to sun light.