INTRODUCTION

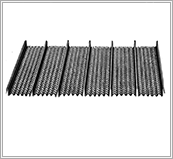

Rockmax Superrib is a galvanized permanent shuttering system with a unique design incorporating mesh and roll formed ribs. This system retains poured concrete achieves a significant reduction in the pressure of concrete normally associated with conventional formwork and provide mechanical keys for construction joints.

It can be placed before reinforcing rods which are installed after by piercing them through the mesh are in the rib. This light and versatile product can be cut and bent to shape. Therefore suiting may applications and can be fitted in less time than traditional formwork. The advantage of Superrib are that no stripping or preparation work the joint is necessary before bonding to any adjacent pour. Also if reinforcement is in place it will allow continuation of fixing without a break.

AREA OF USES

Formwork construction joints, the formwork remain permanently placed the pored concrete and the surface after casting which requires no bonding medium for the next pour. The quality of the bonding between new concrete and old is strong and durable than normal shuttering method, without any sort of damage on concrete. Superrib is using in many large construction structures, sewerage plants, storage tanks dry docks, foundation, and bridge decks are some among them. The super-rib will be permanently places after casting that reduces the cost of shutter removal, only support removal is required.

ADVANTAGES

APPLICATION AND INSTALLATION

STANDARD

BS 6399 part 1, 1984

ASTM A653/A653M

CONCRETE STABILITY

The application of the Superrib is suitable in most concrete mixes with slump between 70mm to 180mm When the application is with concrete slump of 180mm and over, a little cementations liquid is expected to seep/leak through the openness of the “keying region” of the Superrib during the initial stage of the concrete pour. However this will not weaken the strength of the concrete core. In this application no vibrator is used.

POURING CONCRETE

Concrete shall not be poured directly against the Superrib. The concrete shall be poured at about 500mm distance away from the Superrib and let it flow towards the Rib. In general, the pour (or initial pour) of concrete should be effected against the ribbed side of the Rib. Excess grout should be removed. Taking care not to disturb the fresh concrete Superrib face while removing any overspill and grout build up on the walings.

PACKAGING

10 Sheet per bundle.

STORAGE

Storage in shade and dry condition Avoid from frost, water, moisture and high temperature.